Ukwenziwa kweglasi yinkqubo emandla ngamandla, malunga nama-75 ukuya kuma-85 ekhulwini amandla asetyenzisiweyo ngexesha lokunyibilika kweglasi.Ukunciphisa ukusetyenziswa kwamandla kulo naliphi na inqanaba lokwenziwa kweglasi kunokuba luncedo ngeendlela ezimbini: okokuqala, ekubeni amandla awona maxabiso abiza kakhulu kwinkqubo yokuvelisa, ukonga amandla kunokukhokelela ekugcinweni ngokuthe ngqo;Okwesibini, kwinkqubo yokuvelisa, ukuphakama kokusetyenziswa kokusebenza kakuhle kwe-thermal, ulawulo oluchanekileyo lwe-viscosity yeglasi etyhidiweyo yolwelo.Oku kwenza ulawulo lomgangatho wemveliso lube lula, nto leyo ekhokelela kugcino lweendleko ngokuthe ngqo ngokucutha inkunkuma.Ngoko refractories esebenzayo kunyeizinto zokufakelwa kwe-thermalziya zibaluleke ngakumbi nangakumbi kwizixhobo zokwenza iglasi.Ngaphambili, iikilni zeglasi bezisetyenziswa kakhulu izixhobo zokugquma i-thermal, kodwa ngokuqhelekileyo kukho i-thermal conductivity ephezulu kwiqondo lokushisa eliphezulu, isiphumo sokugcina amandla asifanelekanga.Ngokunyuka kwemfuno yokonga amandla, uhlobo lwemathiriyeli yokugquma i-microporous isetyenziswa ngakumbi nangakumbi kwimveliso yeglasi.

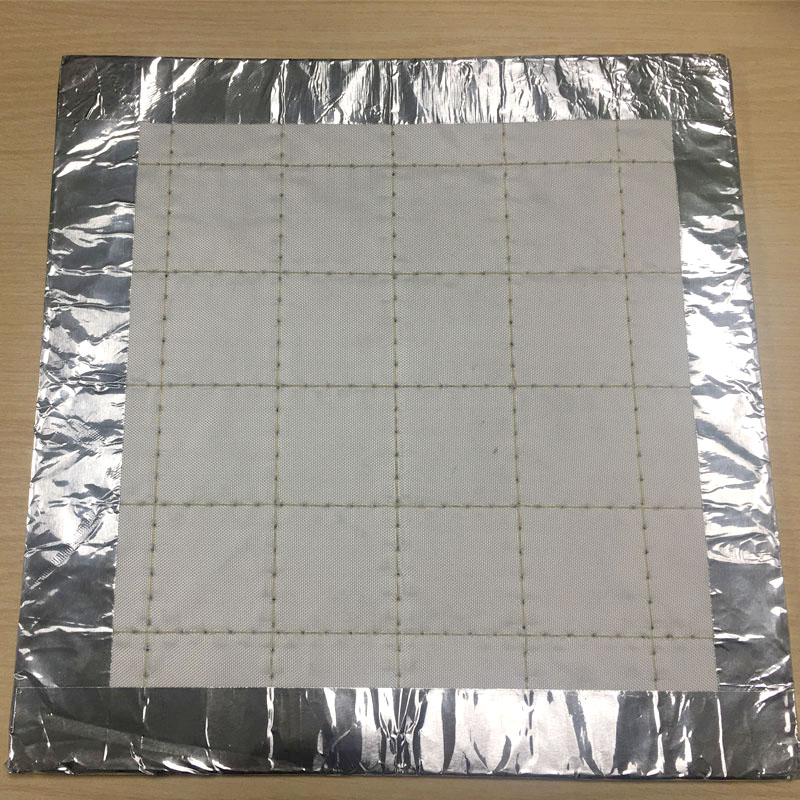

I-Microporous Insulation yimathiriyeli yeprofayile entsha ephuhliswe ngokusekelwe kumgaqo we-microporous insulation.Amacandelo aphambili yi-ultrafine silicon oxide powder enobubanzi obuyi-7 ukuya kwi-nanometers ezili-12, izinto ezixubeneyo zokukhusela ukusasazeka kwemitha, kwaye zicinezelwe bubuchwepheshe obukhethekileyo.Umphezulu wemveliso unokugqunywa ngelaphu lefiber yeglasi, iifom eziqhelekileyo ziluhlobo olucaba, uhlobo lokuqengqeleka.Uhlobo lwebhloko, uhlobo lwengubo ethambileyo, njl njl.Kwinkqubo yokuveliswa kweglasi, umsebenzi oyintloko we-microporous insulating plate kukunciphisa ukulahleka kobushushu.Ukunciphisa ukusetyenziswa kwamandla: phucula indawo yokusebenza yefektri;Ukwandisa ubomi bezixhobo zokunciphisa ubukhulu bomgangatho wokushisa ubushushu, ukunciphisa umthamo wezixhobo;Yandisa umthamo wangaphakathi.Ukunciphisa ukugcinwa kobushushu kwi-insulation layer kunye nokunyusa izinga lokushisa

Ukulahleka kobushushu kufuneka kulawulwe ngononophelo kuyo yonke inkqubo yokwenza iglasi ukuze kuqinisekiswe ukusebenza kakuhle kwamandla kunye nefuthe elincinci lokusingqongileyo.Eyona ndlela isebenzayo yokugcina ubushushu kukusebenzisa inkqubo ye-adiabatic microporous, enezi nzuzo zilandelayo:

Eyona conductivity iphantsi thermal, ukusebenza kwayo adiabatic yi adiabatic impahla yemveli ukungcangcazela amaxesha amaninzi

Eyona conductivity iphantsi thermal, ukusebenza kwayo adiabatic yi adiabatic impahla yemveli ukungcangcazela amaxesha amaninzi

Ingasetyenziselwa ukuveliswa kweemveliso ezahlukeneyo kunye neemveliso ezenziwe ngaphambili, kwaye inokwakheka kwangaphambili okanye isikwe ngokulula kwaye ilungiswe kwindawo yokufakela.

Eyona ndlela incinci, ilula kakhulu i-adiabatic system.Ubunzima benkqubo yokugquma kuphela ikota yobunzima bezinto eziqhelekileyo zokugquma

Akukho fayibha ephefumlayo, ayinabungozi ngokupheleleyo, inobuhlobo nokusingqongileyo.Ikhuselekile kwaye icocekile ukuyisebenzisa, ngokuhambelana nokhuseleko lwamazwe ngamazwe kunye nemigaqo yezempilo

Iyakwazi ukusebenza ngokuqhubekayo kunye nozinzile kwi-800 °C -1000 °C.Ngokucutheka komgca ongakhathaliyo kwiqondo lobushushu eliphezulu, ukusebenza kakuhle kokurisayikilisha, akukho monakalo.

Ngenxa yokuvuthwa okuqhubekayo kwetekhnoloji yesicelo se-nano microporous heat insulation materials, isicelo esiphumeleleyo kwezinye iifektri zeglasi kwiminyaka yakutshanje ibonise ukuba izinto zinempembelelo ephawulekayo ekongeni amandla kunye nokunciphisa ukukhutshwa.Nangona xa kuthelekiswa nezinto zemveli zokufudumeza ubushushu, iindleko zokuqala zotyalo-mali ziya kunyuswa ukuya kumlinganiselo othile, kodwa ukuncitshiswa kamva kwenzuzo yokusetyenziswa kwamandla kubalulekile, kuthathelwa ingqalelo iinzuzo zexesha elide eziziswa kukugcinwa kwamandla kunye nokunciphisa ukukhutshwa kwamandla, olo tyalo-mali lufanelekile.Kubonwa kwangaphambili ukuba phantsi kweemfuno ezikhulayo zokugcinwa kwamandla kunye nokunciphisa ukukhutshwa, ukusetyenziswa kwezixhobo zokutshisa ukushisa kwe-nano-porous kwishishini leglasi kuya kuthandwa ngakumbi.

Zerothermo sigxile kwitekhnoloji yokucoca itekhnoloji engaphezulu kweminyaka engama-20, iimveliso zethu eziphambili: iipaneli zokugquma i-vacuum ezisekwe kwizinto ezingundoqo ze-silica zokugonya, ezonyango, kwikhonkco elibandayo, ifriji, i-vacuum insulation edibeneyo kunye nephaneli yokuhlobisa,iglasi yokucoca, tshayela iingcango neefestile ezigqunyiweyo.Ukuba ufuna ukufunda ulwazi oluninzi malunga Iiphaneli ze-vacuum insulation zerothermo,Nceda uzive ukhululekile ukuqhagamshelana nathi, kwakhona wamkelekile ukuba undwendwele umzi-mveliso wethu.

Umphathi weThengi: Mike Xu

Ifowuni: +86 13378245612/13880795380

E-mail:mike@zerothermo.com

Iwebhusayithi:https://www.zerothermovip.com

Ixesha lokuposa: Feb-23-2023